What is Powder Coating?

Powder coating is a dry finishing process where a powder is fused with the surface of the metal. After baking in an industrial strength curing oven, the result is an ultra-strong finish coating that will provide decades of protection to your products.

Raw & Unfinished Steel Characteristics

RAW STEEL

Metal surfaces scratch, dent, tarnish and rust over time, and rust will eat through your product and cause customers to choose a product that lasts longer.

Metal is coated in order to slow down this process.

PAINT VS POWDER COATING

Paint is a common coating people apply to metal, however paint is not durable, and will peel and your metal will rust very quickly compared to the highly sustainable powder coating process.

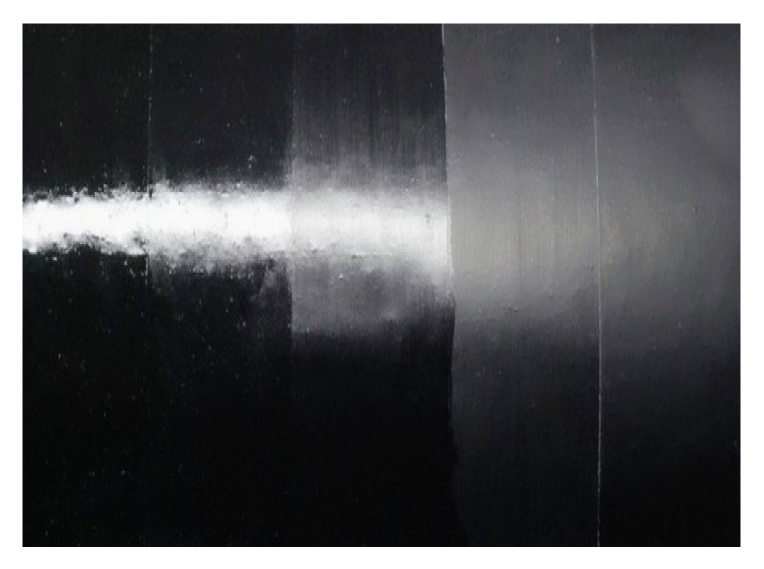

Our Process

Finishes

Putting the right finish on your products is very important. Available finishes come in a spectrum that ranges from a basic matte, to a high gloss sheen. The oven time and temperature are adjusted to achieve your desired look.

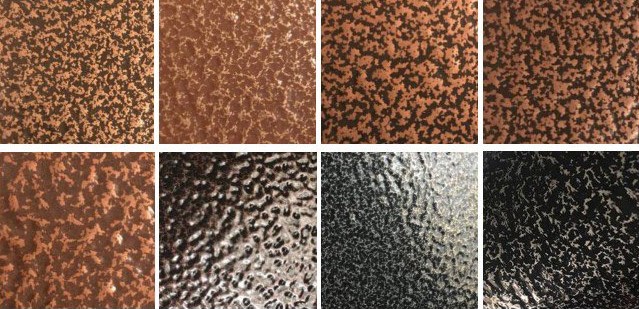

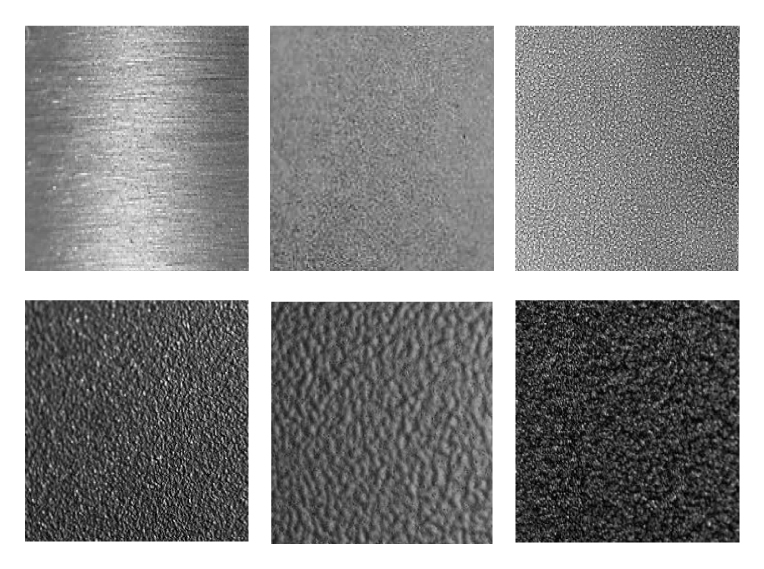

Textures

Your projects may require a particular thickness of metal. There are several options including fine grain, course grain vein, crocodile patterns, and palpable textures. The more course of the texture that you are wanting, the thicker the final metal will be.

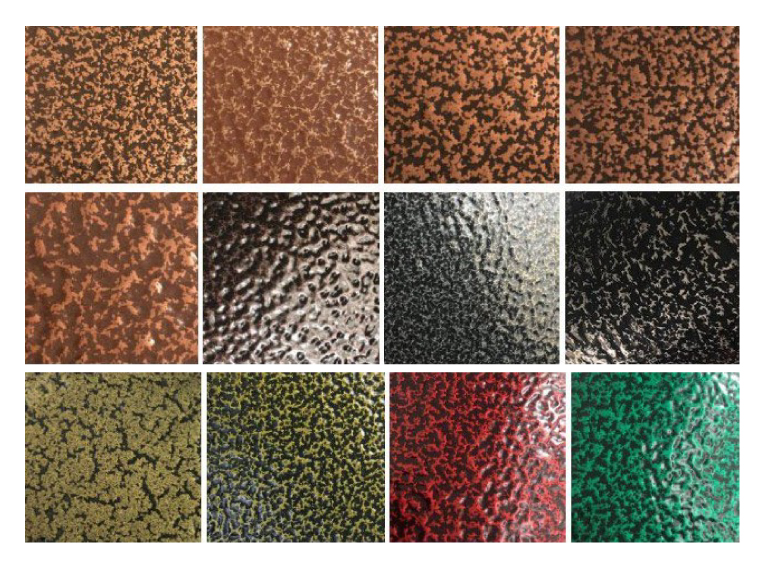

Add Color

Whether you want a traditional neutral color like white, grey, tan or beige, or bright bold colors, the color options are endless. There are industry standard colors that are always available, but other shades can be special ordered for your projects.

Endless Color, Sheen and Texture Possibilities

Think big. Quest has endless options to roll out in front of you to ensure your product turns out exactly the way you need it to be–down to the smallest details.